Page 5 of 6

Re: Projecting an SLS system: Scanning precision

Posted: 16 Nov 2017, 20:04

by mading

Did some work.

Fusion was not exticing: various areas are not overlapped.

It ain't bad (1500-2), but I lack in alignement precision.

Do I have to work on scan quality (distorsion)? I guess wavyness is partially due to optical refraction of lights in wood. But misalignement here is an issue to be solved.

Re: Projecting an SLS system: Scanning precision

Posted: 17 Nov 2017, 05:34

by 3dxcan

Scan the calibration panel after calibration process and send me the stl file. I'll show you how much distortion you're having.

Re: Projecting an SLS system: Scanning precision

Posted: 17 Nov 2017, 07:44

by Stive_Rad0

3dxcan wrote: ↑17 Nov 2017, 05:34

Scan the calibration panel after calibration process and send me the stl file. I'll show you how much distortion you're having.

Hi

Can I know how can you measure distortion by scanning calib panel?

Re: Projecting an SLS system: Scanning precision

Posted: 17 Nov 2017, 08:11

by 3dxcan

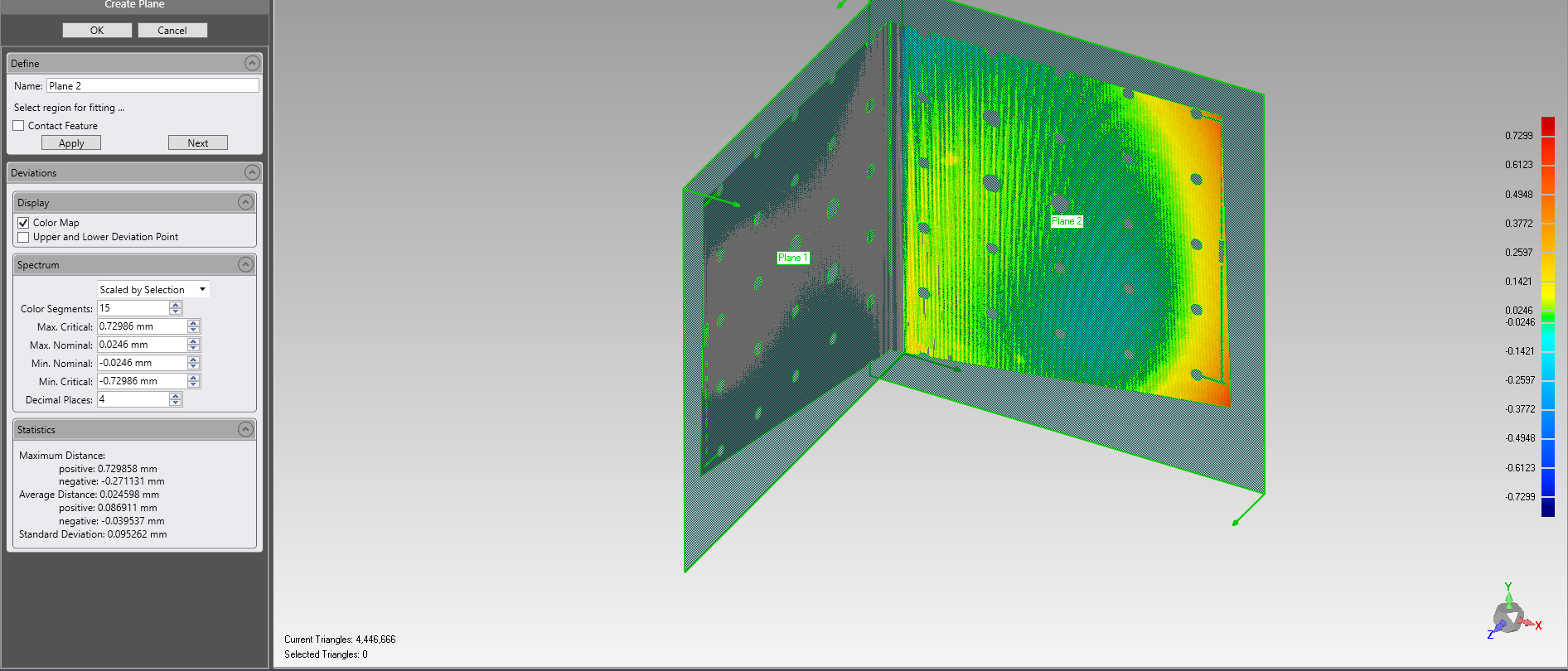

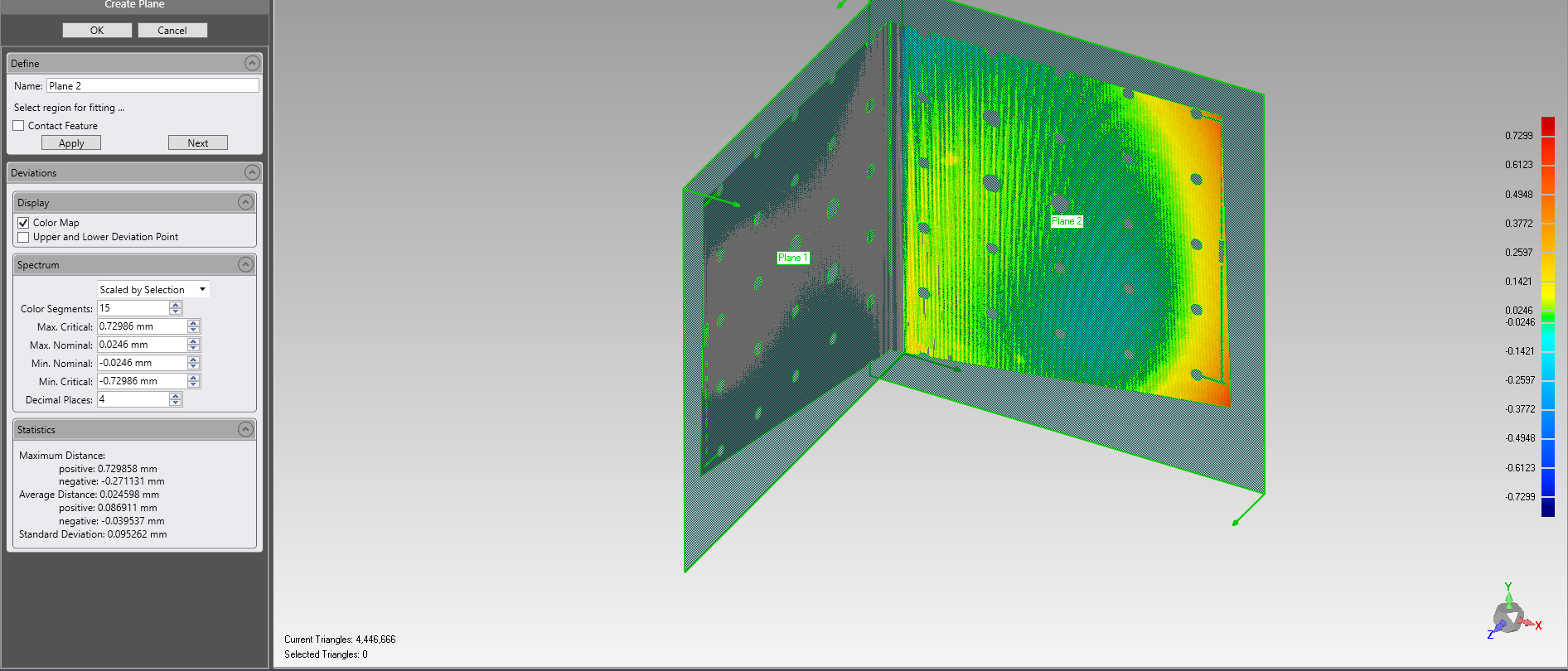

i use geomagic to determine the amount of deviation from plane you're getting on each side of the calibration panel.I call it the disortion map. thats a good indicator of the amount of distortion.

as an example this isnt a favourable:

Re: Projecting an SLS system: Scanning precision

Posted: 17 Nov 2017, 08:20

by mading

Many thanks 3dxcan.

ASAP I'll send you the stl.

Do you use also GOM inspect? I find it very powerful, fast and stable (and free).

If anybody in the forum is using it, I'll appreciate an indication of doing the same verification with GOM.

Re: Projecting an SLS system: Scanning precision

Posted: 17 Nov 2017, 09:24

by mading

Hi to all, I gave a tried to GOM inspect 2016, free version:

I have to check the perpendicularity of my panel: it is measured as 90.05°:

Then I can fit planes (easy and straighforward):

Here you have deviations from fitted planes:

Re: Projecting an SLS system: Scanning precision

Posted: 17 Nov 2017, 13:46

by 3dxcan

mading wrote: ↑17 Nov 2017, 09:24

Hi to all, I gave a tried to GOM inspect 2016, free version:

I have to check the perpendicularity of my panel: it is measured as 90.05°:

90.05°.jpg

Then I can fit planes (easy and straighforward):

Clip_4.jpg

Here you have deviations from fitted planes:

Clip_2.jpg Clip.jpg

as you see in the pics, you have a center of yellow and green (~0.05 divation) which happens to be accelerating out of the divation zone (-0.15) as you move toward the calibration edges, gray areas on the corner are our of tolerance zone (-0.15,0.15).Its a lens problem. someone with a decent lens should give us his result.

what size of calibration panel are you using? whats the format of the camera sensor (eg 2/3", etc) and lens? what type of camera? global/rolling?

Re: Projecting an SLS system: Scanning precision

Posted: 17 Nov 2017, 14:32

by mading

camera spec (see previous post):

http://www.oemcameras.com/dmk-23ux236.htm

aperture: around f12

lens: Cosmicar/Pentax 12 mm f1.2

panel: 110 mm

Re: Projecting an SLS system: Scanning precision

Posted: 17 Nov 2017, 14:59

by Stive_Rad0

mading wrote: ↑17 Nov 2017, 08:20

Many thanks 3dxcan.

ASAP I'll send you the stl.

Do you use also GOM inspect? I find it very powerful, fast and stable (and free).

If anybody in the forum is using it, I'll appreciate an indication of doing the same verification with GOM.

by this method it is not defined the source of error (badly made calib panel or other sources). in all cases you may get the same deformation on mesh.

Re: Projecting an SLS system: Scanning precision

Posted: 17 Nov 2017, 15:27

by mading

I agree there's plenty of room for further improvements, starting from panels.

Panels are made of:

-melamine particle board 19mm

-dots printed with inkjet printer on photographic paper

-paper glued with spray contact glue

I already found a visible deformation with my knife edge ruler.

Sorry for posting things on separate posts.

I could scan a "really flat" surface (less than 0.01 mm) and see what happens.